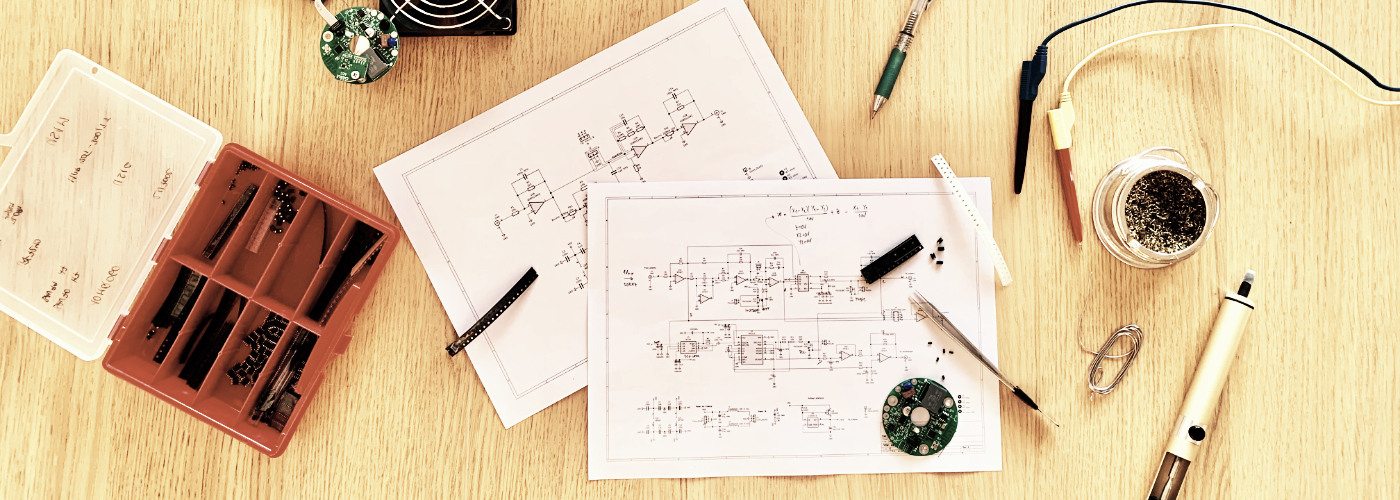

Measuring and test-tools, various prototypes from a single unit volume, create a PCB and its manufacturing data

AdafruitIO

📈📊📉 𝐃𝐚𝐭𝐚 𝐯𝐢𝐬𝐮𝐚𝐥𝐢𝐬𝐚𝐭𝐢𝐨𝐧 𝐢𝐬 𝐛𝐞𝐚𝐮𝐭𝐢𝐟𝐮𝐥 Nearly six years ago, I transitioned away from programming and got busy with other ventures. Two years ago, I bid adieu to the world of coding. It was not an easy decision, but it was